Manufacturing Safety Solutions Intelligent Industrial Protection

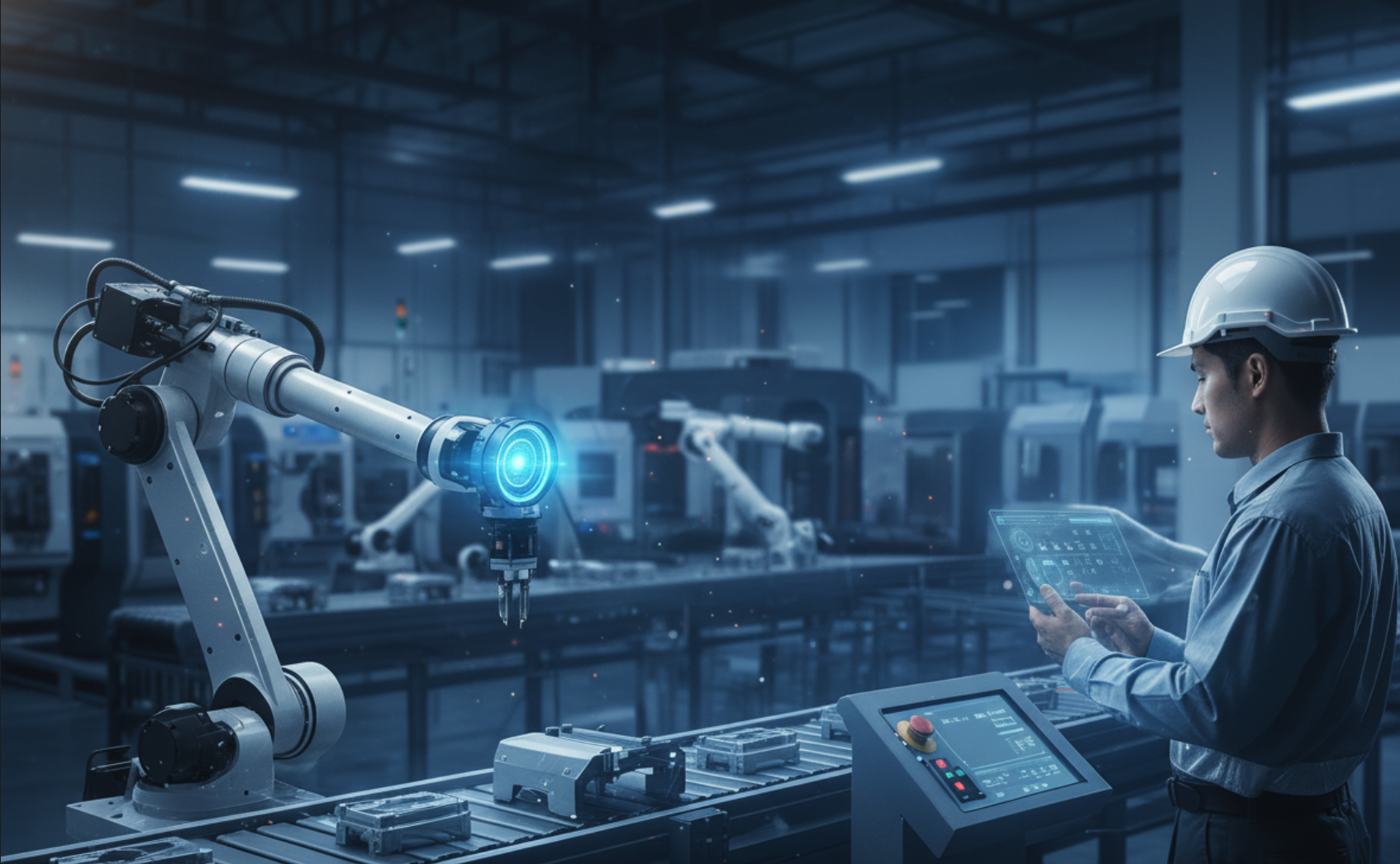

Transform your manufacturing operations with AI-powered safety monitoring. Prevent equipment failures, protect workers, and ensure compliance while maximizing operational efficiency and reducing costs.

Manufacturing Safety Challenges

Modern manufacturing faces unprecedented safety and operational challenges. Traditional reactive approaches are no longer sufficient.

Equipment Downtime

Unplanned equipment failures cost manufacturers millions in downtime, lost productivity, and emergency repairs.

Worker Safety

Manufacturing accounts for significant workplace injuries, with many incidents being preventable through better monitoring.

Compliance Complexity

Increasing regulatory requirements and safety standards create complex compliance challenges for manufacturers.

Data Fragmentation

Siloed systems and fragmented data prevent comprehensive visibility into operations and safety conditions.

Fortisys Manufacturing Solutions

Comprehensive safety solutions designed specifically for manufacturing environments, from small facilities to large-scale industrial operations.

Equipment Monitoring

Real-time monitoring of critical equipment with AI-powered anomaly detection and predictive failure analysis.

- Vibration and temperature monitoring

- Motor current signature analysis

- Oil analysis and contamination detection

- Bearing and gear condition assessment

- Real-time equipment health dashboards

Predictive Maintenance

Advanced machine learning algorithms predict equipment failures weeks in advance, enabling proactive maintenance scheduling.

- Failure prediction algorithms

- Maintenance scheduling optimization

- Parts inventory management

- Technician workflow automation

- Maintenance history analytics

Worker Safety Tracking

Comprehensive worker safety monitoring including PPE compliance, location tracking, and environmental hazard detection.

- PPE compliance monitoring

- Worker location and proximity alerts

- Environmental hazard detection

- Emergency response automation

- Safety training compliance tracking

Compliance Reporting

Automated compliance reporting and audit trail generation for regulatory requirements and safety standards.

- OSHA compliance reporting

- ISO 45001 audit trails

- Environmental compliance tracking

- Automated report generation

- Regulatory change notifications

Manufacturing Use Cases

See how Fortisys transforms safety and operations across different manufacturing environments and processes.

Automotive Assembly

Monitor assembly line equipment, track worker safety compliance, and ensure quality control in automotive manufacturing facilities.

- Robotic arm condition monitoring

- Conveyor system health tracking

- Paint booth environmental monitoring

- Worker proximity safety systems

- Quality control station monitoring

Food Processing

Ensure food safety compliance, monitor processing equipment, and maintain hygiene standards in food manufacturing facilities.

- Temperature and humidity monitoring

- Contamination detection systems

- Equipment sanitation tracking

- Cold chain monitoring

- HACCP compliance automation

Chemical Processing

Monitor hazardous processes, ensure worker safety, and maintain compliance in chemical manufacturing environments.

- Gas leak detection systems

- Pressure and temperature monitoring

- Chemical storage tank monitoring

- Emergency response automation

- Environmental emission tracking

Manufacturing ROI Calculator

See the potential return on investment for implementing Fortisys in your manufacturing facility.

Within first 12 months

For mid-size facilities

Typical implementation

Implementation Process

Seamless deployment with minimal disruption to your manufacturing operations. Our proven methodology ensures quick time to value.

Assessment & Planning

Comprehensive facility assessment, safety audit, and custom implementation plan development.

Infrastructure Setup

IoT sensor installation, network configuration, and integration with existing systems.

AI Model Training

Custom AI model training using your facility data and optimization for your specific environment.

Go-Live & Training

System activation, team training, and ongoing support to ensure successful adoption.

Transform Your Manufacturing Safety

Join leading manufacturers who trust Fortisys to protect their workers, optimize operations, and ensure compliance.